Bringing your idea to life requires more than just imagination it takes planning, creativity, and the right tools. One of the most critical steps in this journey is learning how to make a prototype. A prototype is essentially a working model of your concept, allowing you to test and refine it before committing to full-scale production. Whether you’re creating a new consumer product, medical device, or technological gadget, a well-designed prototype is your key to success.

At GID Company, we specialize in helping innovators across the United States, especially in states like California, Texas, Florida, and Georgia turn their ideas into functional products. Prototyping is at the heart of what we do. We don’t just create prototypes we offer tailored solutions that suit your needs and vision, ensuring that your product concept is market-ready.

This article will guide you through how to make a prototype and show you how GID Company can assist you at every stage, from the initial concept to the final product.

How To Get A Prototype Made With GID Company?

When it comes to creating a prototype, having the right partner can make all the difference. GID Company brings decades of experience and industry knowledge to every project, making the prototype development process seamless and efficient. We are more than just a service provider; we are your trusted partner in bringing your idea to life.

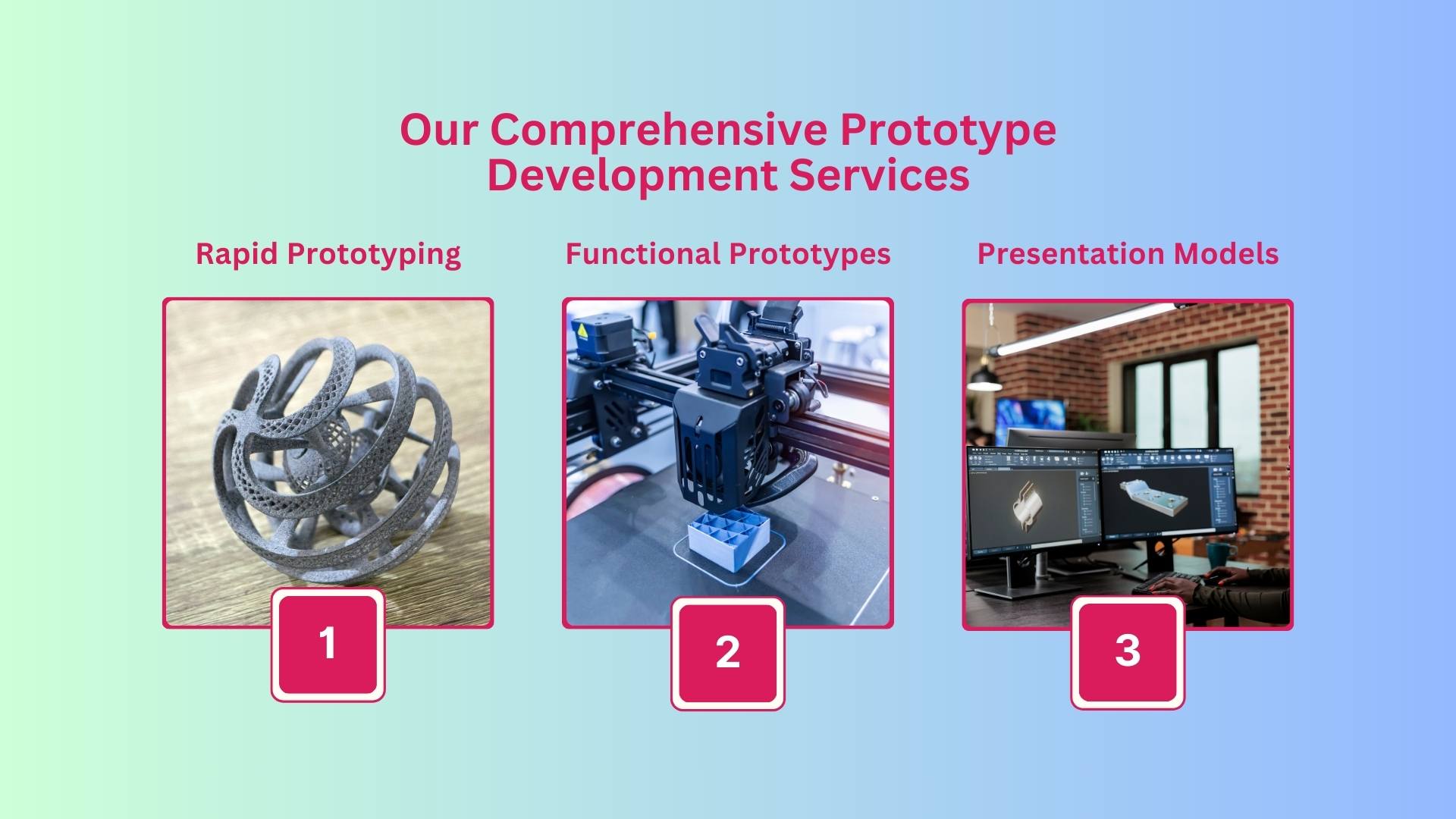

Our Comprehensive Prototype Development Services

Wondering how to get a prototype made? At GID Company, we offer end-to-end services to ensure your product reaches its full potential. From concept to design, material selection, and manufacturing, our team of experts guides you through every phase of development. Whether you need a rough product prototype to test functionality or a polished model to present to investors, we’ve got you covered.

Our team excels in various types of prototyping, including:

- Rapid Prototyping: Using cutting-edge technology like 3D printing to quickly create models.

- Functional Prototypes: Fully operational versions of your concept for real-world testing.

- Presentation Models: Polished, visually appealing prototypes designed for investor pitches or exhibitions.

For example, we helped a startup in Florida create a groundbreaking product prototype for a medical device. By working closely with their team, we transformed their idea into a functional prototype that passed all regulatory testing and attracted investor interest.

Tailored Solutions for Different Industries

No two projects are the same, which is why we customize our services to suit the unique needs of each client. Whether you are an entrepreneur launching a new product in Texas or a large company developing a tech solution in California, GID Company offers solutions tailored to your specific requirements.

Our expertise spans a wide range of industries, including:

- Consumer products

- Medical devices

- Electronics

- Automotive parts

For instance, a prototype example of our work involved creating an innovative home appliance for a client in Georgia. From the initial sketch to the final product prototype, we worked closely with them to ensure that the design, materials, and functionality met their exact specifications.

Steps to Build a Product Prototype

Creating a prototype is an essential phase in turning your idea into a tangible product. It’s the process that allows you to test, refine, and improve your concept before it hits the market. Understanding how to make a prototype involves breaking down the development process into several key stages. These steps ensure that your product is well-designed, functional, and ready for production. At GID Company, we streamline this process, offering you expert guidance and cutting-edge technology to bring your ideas to life.

Step 1: Idea Refinement

The first step in learning how to make a prototype is refining your initial idea. While you may have a broad vision of your product, it’s important to flesh out the details. This includes determining the primary function of your product, who your target audience is, and what unique value your product offers.

GID Company works closely with clients to transform these early ideas into concrete plans. We collaborate with you to clarify features, design specifications, and functionality. This stage also involves sketching out a basic layout or design, which serves as a blueprint for the next stages.

For example, when a client from California approached us with an idea for a home gadget, we helped them define the core functionality and aesthetics of their product. This early-stage collaboration laid the groundwork for a successful product prototype.

Step 2: 3D Modeling

Once the concept is clear, the next step in how to make a prototype is creating a 3D model. At GID Company, we use advanced CAD (Computer-Aided Design) software to bring your idea to life digitally. This 3D model allows you to visualize the product from all angles, ensuring that the design is functional and meets your needs before any physical prototype is made.

During this phase, we also determine the materials that will best suit your product’s function and design. Whether your prototype needs to be lightweight, durable, or flexible, GID Company’s team can recommend the ideal material for your project.

A prototype example of our work involves designing a high-precision 3D model for a medical device startup in Florida. The 3D model allowed the client to make critical adjustments before moving on to the production of the physical prototype.

Step 3: Prototype Fabrication

After finalizing the 3D model, the next stage in how to make a prototype is selecting the right materials and building the first physical model. The material selection is crucial since it determines how your prototype will perform during testing and evaluation. At GID Company, we work with a wide range of materials, from plastics to metals, depending on the product’s requirements.

Using technologies like 3D printing, CNC machining, or injection molding, we fabricate your product prototype with precision and care. GID Company ensures that the prototype not only matches the design but also functions as intended, allowing you to test it thoroughly.

For instance, a startup from Texas worked with us to develop a fully operational product prototype for an automotive accessory. We helped them choose durable materials and produced the first working prototype, which they later showcased to investors.

Step 4: Testing and Iteration

The prototype is more than just a model; it’s a tool for testing and refinement. Once the prototype is built, it’s time to put it through rigorous testing. This is where you evaluate its functionality, durability, and overall performance. Testing can reveal flaws or areas of improvement, which allows you to make necessary changes before moving into production.

At GID Company, we work closely with our clients to test their prototypes and gather feedback. If you’re wondering how to make a prototype, our process guides you through each step, ensuring that the final product is not only functional but also optimized for the market. We take feedback from real-world testing and use it to refine the prototype, making sure every adjustment brings you closer to a flawless product.

A prototype example of this phase is a client from Arizona who tested their consumer product prototype with a focus group. Based on the feedback, we made minor tweaks to the design, improving usability and functionality.

Step 5: Final Prototype

The final step in how to make a prototype is preparing it for pre-production. Once all testing and adjustments are completed, the prototype is finalized. At this stage, the prototype should closely resemble the final product in both appearance and function.

GID Company ensures that your final product prototype is production-ready. We provide detailed documentation and manufacturing support, so you can seamlessly transition from prototyping to full-scale production. Whether you’re looking to manufacture locally or overseas, GID Company offers guidance every step of the way.

For clients wondering how to get a prototype made that’s ready for mass production, GID Company provides the resources and expertise to take your project to the next level.

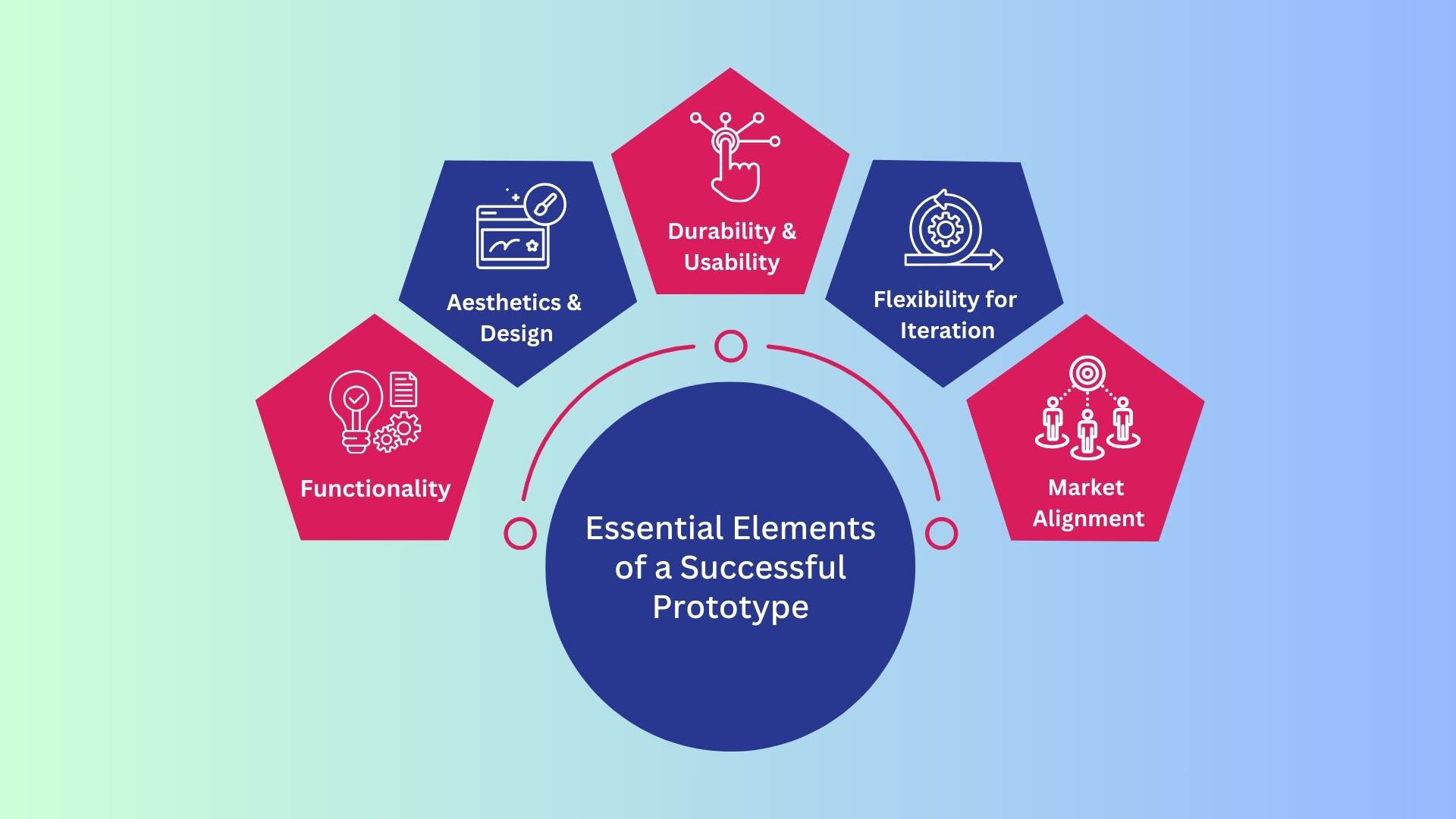

Essential Elements of a Successful Prototype

When learning how to make a prototype, it’s important to understand what makes a prototype effective. A successful prototype goes beyond simply looking like the final product; it must demonstrate key functionalities, reflect the design, and help stakeholders evaluate the product’s market potential. At GID Company, we work closely with clients to ensure that each product prototype we create meets these essential criteria.

Let’s break down the critical elements every prototype should have to maximize its effectiveness.

Functionality: The Core of Every Prototype

The primary purpose of any prototype is to test and prove the functionality of a product. No matter how great the design looks, if the prototype doesn’t function as expected, it’s unlikely to gain traction. Therefore, when you’re figuring out how to make a prototype, focusing on functionality is crucial.

At GID Company, we help you create prototypes that are more than just visual models—they are fully functional representations of your concept. From the mechanics to the electronics, we ensure that your product prototype operates exactly as it would in real-life conditions. For example, when a client from Texas needed a working prototype for a consumer electronics product, we developed a fully operational model that could be tested for performance and usability.

Ensuring functionality early in the process helps reduce costly revisions later on and gives you a clear understanding of whether the product will meet customer expectations.

Aesthetics and Design: Visual Appeal Matters

While functionality is the foundation, the design and aesthetics of your prototype also play an important role. A well-designed prototype should closely resemble the final product in both appearance and feel. This is especially important when presenting your prototype to investors, stakeholders, or potential customers. When learning how to make a prototype, understanding the balance between functionality and aesthetics is key.

At GID Company, we ensure that the prototype not only works well but also looks professional. We use advanced techniques to finish the prototype so that it mirrors the final product. This attention to detail is vital in making a good impression, particularly for companies seeking investment or early market validation. A prototype example we developed for a startup in Florida included polished, high-quality finishes that impressed investors and helped secure funding.

By combining a functional model with attractive design elements, GID Company helps clients showcase their products in the best possible light.

Durability and Usability: Real-World Testing

When learning how to make a prototype, it’s important to ensure that your model is built to withstand real-world conditions. This involves testing the durability and usability of the product in various environments. A prototype must be able to handle normal wear and tear while still performing as intended.

GID Company focuses on creating durable prototypes that can be used for extensive testing. We select materials that match the final product’s intended use, ensuring that the prototype can be tested in realistic conditions. This type of rigorous testing is crucial, especially for products that need to meet industry standards or regulatory requirements. For instance, we developed a durable product prototype for a medical device company in California, which needed to pass FDA compliance tests.

By building a prototype with durability in mind, you reduce the chances of failure during real-world testing and ensure that the final product will hold up under everyday use.

Flexibility for Iteration: Evolving with Feedback

A prototype is rarely perfect on the first try. One of the most important steps in how to make a prototype is leaving room for iterations. The feedback you receive from testing and presenting your prototype will likely result in changes to the design, functionality, or materials. Having a flexible design that can evolve with each round of feedback is essential for ensuring that your final product is optimized for success.

At GID Company, we prioritize flexibility in our prototyping process. Our team works with you to iterate and refine the prototype based on feedback from testing or market evaluations. For instance, we worked with a company in Utah to modify their product prototype multiple times until it met all of their performance and design goals.

This iterative approach ensures that by the time the final product is ready for production, it is as close to perfect as possible.

Market Alignment: Building for Success

Lastly, a successful prototype must be aligned with market needs and customer expectations. A great design and working model won’t lead to success if it doesn’t meet the demands of your target audience. That’s why, when understanding how to make a prototype, it’s essential to keep your customers in mind throughout the development process.

GID Company helps clients ensure that their prototypes are tailored to their specific market. Whether it’s a consumer product for households or a specialized industrial tool, we consider factors like usability, design preferences, and industry standards to align the prototype with customer expectations. If you’re wondering how to make a prototype, an example of our work is with a client in Georgia, where we tailored the design and functionality of a home appliance to meet customer needs, resulting in strong market interest after testing.

By aligning your prototype with market demands, you increase your chances of success once the product is launched.

Conclusion

Prototyping is an essential step in transforming your idea into a market-ready product. Understanding how to make a prototype can seem overwhelming, but with the right team by your side, it becomes an exciting and rewarding process. At GID Company, we are committed to helping you through every stage, from the initial concept to a fully functional product prototype that meets industry standards and market demands.

Whether you’re just starting out and need help figuring out how to make a prototype or how to get one made, or you’re ready to refine your product for production, GID Company has the expertise and technology to bring your vision to life. We serve clients across the U.S., with a focus on areas like California, Texas, Florida, and Georgia, ensuring your project gets the attention and support it deserves. Request your free quote today!

Read Also: Getting a Product Prototype Developed