Prototype Development of Products with Electronics: From Concept to Creation

Prototype Development of Products: Have a brilliant idea for a new electromechanical product? To bring your concept to life and launch it successfully, the first step is prototype development. Prototype development of products with electronics is crucial for testing and refining your ideas before they reach consumers. So, where should you start with the prototype development of products with electronics?

The prototype development of products with electronics presents challenges and can be costly. Results aren’t immediate without a prototype, but by breaking the prototype development process into manageable steps, you can achieve a successful working model.

The prototype development of most products with electronics typically involves two key segments: the electronics segment and the plastic case segment. Let’s explore each of these aspects in detail.

The Electronics Segment

Prototype development of products with electronics involves four key steps. If you are skilled in electronics or a DIY enthusiast, you may bypass the first two steps. Otherwise, you should collaborate with a company specializing in the prototype development of products to ensure successful outcomes in electronics prototypes.

Step 1. Create the Schematic

The first step in the development of the electronics segment is the creation of the electronics blueprint or schematic for your product. This blueprint states all the important details of building the electronics segment, including how the necessary components and modules are connected.

Which components are needed will also be specified in the schematic. A bill of materials (BOM) or associated list will be prepared, itemizing every electronic item.

Step 2. Develop a Basic Prototype

Depending on your project and your budget, you may or may not want to develop a basic prototype of the electronics segment.

To create basic prototypes for the electronics segment, you can use breadboards. Utilizing breadboards, you can somewhat crudely, but fairly quickly connect various electronic components. If your project requires advanced electronics, you may also use ready-to-use modules like the Raspberry Pi and Arduino.

Step 3. Design a PCB Layout

You will, at some point, require a production-quality prototype of your conceived product. To create a production-quality prototype, you will require the design and creation of a PCB (printed circuit board).

A printed circuit board is a custom-designed board that holds and connects all the necessary electronic components. Utilizing a special computer application, electronic engineers can turn the schematic of the electronics segment of the conceived product into a virtual layout. Designing a PCB layout is challenging because anything out-of-place can have a big impact on the performance of the final product.

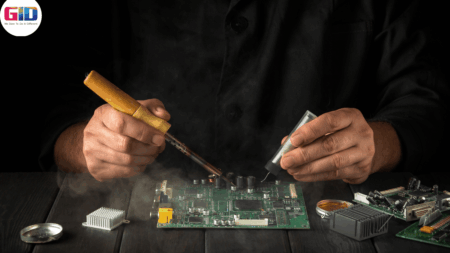

Step 4. Fabrication of the PCBs & Assembly of the Electronic Components

After having a definitive PCB layout, you will need to send the layout to an electronics prototype development company for construction. Such a prototype development company will first fabricate empty PCBs.

After the fabrication of the PCBs, the next step is to assemble the various components on the PCBs through soldering. Most of the modern electronic components are minute and compact, making it very difficult to solder them manually. Therefore, a product prototype development company might employ automated machines to solder the compact and minute electronic components.

The Plastic Case Segment

Most products with electronics need some enclosure, and plastic cases are often the best choice. To create a custom-shaped plastic case for your prototype, you will need to utilize 3D printing or CNC machining.

Step 1. Create a 3D Model

You need to first design a 3D computer model of the required plastic parts. Unless you are proficient at creating 3D computer models, you will need someone expert for this step.

Even if you are capable of creating 3D computer models yourself, the computer software required to create definitive 3D models is very expensive; hence, it may be in your best interest to hire a 3D modeling expert.

Step 2. 3D Printing

After finalizing the 3D model of the plastic case or other components, you can advance the prototype development of products by sending the design files to a 3D printer for swift and efficient prototyping. If you lack access to a 3D printer, consider engaging a prototype shop that specializes in the prototype development of products with 3D printing services.

Alternatively, you might choose to acquire your own 3D printer. Over recent years, 3D printers have become affordable enough for personal use, enhancing the prototype development of products at home.

For the large-scale production of certain plastic cases and parts, however, a completely different technology is utilized. It is called high-pressure injection molding. Shifting a plastic design from a mere prototype to full-scale production is a complex as well as an expensive process. Therefore, teaming up with a plastic product manufacturer, that specializes in plastic product manufacturing with different techniques, will be a wise move on your part.Prototype development of products is crucial.

With a working prototype in hand, you can advance in the prototype development of products by engaging potential stakeholders, gathering customer feedback, and securing a mass manufacturing partner. The journey to success for products with electronics starts with the effective prototype development of products.

If you need help with prototype development for products with electronics, then get in touch with GID Company. A new product prototype development company in California, USA, GID Company utilizes state-of-the-art technologies in order to develop precise product prototypes quickly and economically.

Aside from product prototype development, GID Company also provides product design, product development, and other product fulfillment services. GID Company also possesses the skills and knowledge of a plastic product manufacturer that helps them develop various plastic parts, components, and cases using different injection molding techniques.

Whether it is the design, development, or prototyping of products with electronics, products with embedded software, mechanical products, electromechanical products, medical device products, or any generic or special-purpose products, GID Company will certainly “GET IT DONE!”

If you have any questions regarding product design, product development, or product prototype development, simply give GID Company a call. Currently, GID Company is offering a free 15-minute telephonic conference. So, just call Jim Grimes at 714-323-1052 between 8:00 AM to 5:00 PM PST.

Read Also: Product Prototype Development and Whether to Go for Prototyping or Not