Every great product begins with an idea. But how do you take that idea from a concept on paper to something tangible and market-ready? This is where prototype manufacturing steps in as a vital process, acting as the bridge between imagination and reality. Whether you’re a startup looking to make your first breakthrough or an established business launching a new product, creating a prototype allows you to test, refine, and validate your ideas before committing to full-scale production.

At GID Company, we specialize in helping businesses of all sizes bring their ideas to life. With years of expertise in product development and prototype manufacturing services, we’re not just here to create prototypes—we’re here to partner with you throughout the entire product development journey.

Our approach is simple but powerful: deliver high-quality prototypes that reflect your vision while optimizing for functionality and manufacturability. With operations spanning California, Texas, Florida, Arizona, and other major states, GID Company is strategically positioned to provide tailored support to businesses across industries. From innovative consumer products to cutting-edge medical devices, we ensure your prototypes are designed and manufactured with precision.

By the end of this article, you’ll have a clear understanding of why prototype manufacturing is critical to product development and how GID Company can help you streamline the process.

Read Also: How Product Development Agencies Accelerate Your Ideas to Market

What is Prototype Manufacturing?

Prototype manufacturing is the process of creating a preliminary version or model of a product. It serves as the first tangible representation of your idea, allowing you to evaluate its design, functionality, and feasibility. Simply put, it’s the crucial step that transforms a concept into something real, testable, and actionable.

The Role of Prototype Manufacturing in Product Development

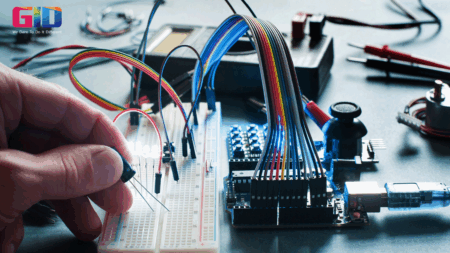

Prototype manufacturing isn’t just about creating a sample; it’s about perfecting your product before committing to large-scale production. By using advanced technologies like 3D printing, CNC machining, and injection molding, businesses can test their product’s design, identify potential issues, and refine their ideas in a cost-effective manner.

At GID Company, we offer a full suite of prototype manufacturing services tailored to meet your specific requirements. Whether you’re developing a simple consumer product or a highly technical industrial component, we ensure every prototype is designed to meet the highest standards of quality and accuracy.

Types of Prototypes We Create

Prototypes come in various forms depending on the stage of development and the purpose they serve. Here’s a quick breakdown:

Visual Prototypes

These focus on the appearance of the product. While they may not function fully, they’re crucial for demonstrating the aesthetics and design to stakeholders or investors.

Functional Prototypes

These are designed to test the functionality and usability of the product. They’re essential for identifying performance issues and refining mechanical features.

Pre-Production Prototypes

These represent the final stage before full production. Pre-production prototypes are used to validate materials, manufacturing processes, and assembly methods.

GID Company’s expertise lies in creating all these types of prototypes, ensuring that businesses have the tools they need to make informed decisions at every stage of the product development process.

A Trusted Partner for Prototype Manufacturing

Partnering with a professional prototype manufacturing company like GID Company brings several advantages. From concept validation to production-ready prototypes, we handle everything under one roof. Our facilities in California and beyond are equipped with state-of-the-art technologies, enabling us to deliver prototypes with unmatched precision and efficiency.

Why Prototype Manufacturing is a Must-Have in Product Development

Many businesses underestimate the importance of prototype manufacturing in the product development cycle. In reality, skipping this critical step can lead to costly mistakes, production delays, and poor product performance. Here’s why creating a prototype is an absolute must for any business developing a new product.

The Purpose of Prototyping

The primary purpose of prototyping is to test and refine your product concept before it goes into full-scale production. Here are three key reasons why businesses rely on prototypes:

Identifying and Resolving Design Flaws

Even the most well-thought-out designs can have hidden flaws. A prototype gives you the chance to uncover these issues early in the process. This not only saves time but also reduces the risk of costly errors during production.

Validating the Functionality of Your Product

Functionality is just as important as design. Prototypes allow you to test whether your product works as intended, ensuring it meets the needs of your target audience.

Building Confidence Among Stakeholders

Whether you’re pitching to investors, presenting to clients, or collaborating with your team, a physical prototype can help communicate your vision more effectively than a digital design or verbal explanation ever could.

At GID Company, we understand the value prototypes bring to the table. That’s why we go beyond just creating physical models. Our prototype manufacturing services include collaborative design reviews, functionality testing, and continuous refinement to ensure your product is ready for the market.

Three Stages Where Prototyping Adds Value

Prototyping isn’t limited to one specific stage of product development. Instead, it plays a crucial role in three distinct phases:

Idea Validation

In the early stages, prototypes are used to test whether your concept is feasible. This stage is all about answering the question, “Will this idea work?”

Design Refinement

Once your idea is validated, prototypes help refine the design. This is where functionality, aesthetics, and usability are perfected.

Manufacturing Optimization

The final stage involves preparing for production. Prototypes ensure that the materials, processes, and assembly methods are optimized for large-scale manufacturing.

By supporting businesses at each of these stages, GID Company has established itself as a trusted prototype manufacturing company. Our team works hand-in-hand with clients to ensure their ideas are not only realized but also perfected.

The GID Company Advantage

What sets GID Company apart is our ability to streamline the prototyping process without compromising quality. With a dedicated team of engineers, designers, and manufacturing specialists, we offer end-to-end support tailored to your specific needs. Whether you’re based in California, Texas, Florida, Arizona, or elsewhere, we’re committed to delivering results that exceed your expectations.

Read Also: How Custom Metal Manufacturing Enhances Prototype Development

How We Streamline the Prototype Development Process

At GID Company, we pride ourselves on making the complex process of prototype development simple, efficient, and effective. Every product we create begins with a clear understanding of your vision, and our goal is to turn that vision into a tangible, market-ready solution. Our streamlined approach to prototype manufacturing ensures that we deliver high-quality prototypes on time and within budget.

Here’s how GID Company executes a seamless prototype development process from start to finish:

Conceptualization: Turning Ideas Into Actionable Plans

The first step in any successful prototype development project is to clarify your idea. What is the product’s purpose? Who will use it? What are the functional and aesthetic requirements?

At this stage, GID Company’s team of expert designers collaborates closely with you to define the objectives of the prototype. We ask the right questions, analyze the market, and identify the technical requirements for your product. This ensures that every decision we make is rooted in your business goals.

By investing time in conceptualization, we set a strong foundation for the rest of the process. Whether it’s a completely new invention or an upgrade to an existing product, GID Company ensures your prototype reflects your vision with precision.

Design and Modeling: The Blueprint for Success

Once the concept is finalized, we move on to creating detailed designs and models. Using advanced CAD (computer-aided design) software, we develop a virtual representation of your product. This step allows us to fine-tune the design and ensure that it meets both functional and aesthetic requirements.

At GID Company, this phase is where innovation truly comes to life. Our team combines creativity with technical expertise to develop designs that are both practical and visually appealing. We also conduct extensive reviews during this stage to eliminate any potential design flaws before moving on to physical production.

Material Selection: Choosing the Right Ingredients

Every product has unique requirements, and the materials used in its construction can make or break its success. GID Company carefully evaluates the needs of your product to select the most suitable materials. Factors like durability, weight, cost, and environmental impact are all considered to ensure your prototype is optimized for performance.

For industries requiring specific standards—such as medical or aerospace—we go the extra mile to source materials that meet regulatory and functional needs. Our tailored approach to material selection sets us apart as a leading prototype manufacturing company.

Prototype Creation: Bringing Your Vision to Life

Finally, the design becomes a reality. This is the stage where your product idea takes shape through prototype manufacturing. Whether it’s through 3D printing, CNC machining, or injection molding, GID Company uses cutting-edge technologies to build prototypes that match the exact specifications laid out during the design phase.

Our manufacturing facilities are equipped with state-of-the-art equipment, enabling us to handle complex projects with ease. No matter how intricate your design, we guarantee precision and quality in every prototype we produce.

By adhering to this meticulous process, GID Company ensures that your prototype isn’t just a product—it’s a proof of concept, a validation of your idea, and a blueprint for production success.

The Benefits of Partnering with a Professional Prototype Manufacturing Company

Choosing the right partner for prototype manufacturing can make a significant difference in the success of your product. By working with an experienced team like GID Company, businesses gain access to expertise, resources, and insights that streamline the product development process. Here are some of the key benefits of working with GID Company for your prototyping needs:

Rapid Turnaround Times: Saving Time Without Compromising Quality

In today’s fast-paced market, time is of the essence. Businesses can’t afford long delays in getting their products to market, and that’s where GID Company excels. Our streamlined processes and advanced technologies allow us to deliver high-quality prototypes within tight deadlines.

We understand that innovation doesn’t wait, which is why our prototype manufacturing services are designed to reduce lead times while maintaining exceptional standards of quality. From the initial design phase to the final prototype, our team ensures every step is completed efficiently and effectively.

Cost Efficiency: Avoiding Expensive Mistakes

Skipping the prototyping stage can result in costly errors during full-scale production. A well-crafted prototype allows businesses to test their designs, identify flaws, and make improvements early in the process. This not only saves money but also ensures that the final product is optimized for success.

At GID Company, we prioritize cost efficiency by focusing on accuracy and attention to detail. Our prototypes are meticulously crafted to provide a clear understanding of the final product, helping businesses avoid expensive revisions later on.

Custom Solutions for Every Project

Every product is unique, and so are its prototyping requirements. GID Company takes pride in offering customized prototype manufacturing services tailored to the specific needs of each client. Whether you’re developing a consumer product, a medical device, or an industrial component, we ensure that the prototype meets your exact specifications.

Our team works closely with you to understand the goals of your project and deliver solutions that exceed expectations. With facilities across California, Florida, Texas, Arizona, and other key locations, we’re well-equipped to provide localized support and expertise.

Access to Advanced Technologies

One of the greatest advantages of working with a professional prototype manufacturing company like GID Company is access to advanced manufacturing technologies. From 3D printing to precision CNC machining, our facilities are equipped with the tools needed to create prototypes with unmatched accuracy.

We stay at the forefront of innovation to ensure our clients receive the best possible solutions. By combining state-of-the-art technology with years of experience, GID Company delivers prototypes that are both innovative and practical.

Collaborative Support Throughout the Process

At GID Company, we believe that successful prototype development requires close collaboration. From the initial brainstorming session to the final prototype, we involve our clients in every step of the process. Our team values your input and works tirelessly to ensure your vision is realized.

This collaborative approach not only ensures that the prototype meets your expectations but also lays the groundwork for a successful production phase. With GID Company by your side, you’ll have a trusted partner to guide you through every stage of prototype manufacturing.

The Benefits of Partnering with a Professional Prototype Manufacturing Company

Partnering with an experienced prototype manufacturing company is one of the smartest decisions you can make during product development. Not only does it help refine your concept, but it also minimizes risks, saves costs, and accelerates the time to market. At GID Company, we specialize in offering end-to-end prototype manufacturing services that empower businesses to move from idea to production seamlessly. Let’s explore the key benefits of working with a trusted partner like GID Company.

Faster Product Development Timelines

Time is a critical factor in product development. Delays in prototyping can push back production, giving competitors a chance to launch similar ideas ahead of you. GID Company understands this urgency, which is why we’ve developed a streamlined approach to prototype manufacturing that ensures rapid turnaround times without compromising quality.

With advanced tools such as 3D printers, CNC machines, and injection molding technologies, we can create accurate prototypes faster than traditional methods. This efficiency allows businesses to test, modify, and finalize their designs quickly, ensuring they remain competitive in the marketplace.

Significant Cost Savings

Developing a product without a prototype often leads to costly errors during manufacturing. Imagine discovering a major design flaw only after production begins—it could mean thousands, if not millions, of dollars wasted on defective units. Prototyping eliminates this risk by identifying issues early in the development cycle.

At GID Company, our prototype manufacturing services help clients save money by resolving design flaws before production. Our team ensures that every prototype is built to specification, allowing businesses to avoid unnecessary expenses while still maintaining a focus on quality and functionality.

Tailored Solutions for Diverse Industries

Each industry has unique requirements when it comes to prototype manufacturing. Whether you’re in consumer electronics, medical technology, automotive design, or industrial equipment, your prototype must reflect the specific demands of your market.

GID Company offers fully customized solutions to meet the diverse needs of our clients. Our team of engineers and designers has experience in a wide range of industries, enabling us to create prototypes that meet technical, aesthetic, and functional expectations. By leveraging our expertise, you can ensure that your product is optimized for its intended use and audience.

Access to Cutting-Edge Technologies

When you work with GID Company, you gain access to the latest advancements in prototype manufacturing services. Our facilities are equipped with state-of-the-art technologies that enable us to produce prototypes with exceptional precision. From detailed 3D models to fully functional prototypes, our capabilities ensure that your product is created to the highest standards.

Our investment in advanced equipment and techniques is just one of the many reasons why GID Company is a leading prototype manufacturing company in California and across the U.S. We’re committed to helping you stay ahead of the curve by delivering innovative solutions that make your product stand out.