You might wonder what’s wrong with diving straight into production with a new product idea. While you may have done market research and identified a promising market, skipping the crucial steps involved in product development can lead to failure. Here’s why understanding the steps involved in product development is vital for success:

Essential Steps Involved in Product Development: A Comprehensive Guide

Step 1: Research

Performing extensive market research is the first step in the steps involved in product development. A market research helps identify the prospect of the new products. Is the conceived product unique? How ergonomic the product should be? Will the product be helpful to the potential customers? Are there any alternatives for the conceived product yet? Answers to these and many other questions shape the success of the new product, and in order to get the answers, performing research is necessary.

Step 2: Product Design

A conceived idea is actually elucidated during the product design stage. In fact, all the detailed drawings, from concept to envisioned final product, are drawn during the product design stage. This is one of the most critical steps involved in product development. If the product is complex, the design process includes Preliminary Product Design and Final Product Design.

A conceived product can be simple or complex in nature. If it is a simple product with few parts or components, the product design process will be a single step. On the other hand, if it is a complex product with numerous parts or components, product design process will be broken down into two sub-steps: Preliminary Product Design and Final Product Design.

Preliminary Product Design:

When a product consists of more parts or components, like an electromechanical power unit, which has over hundreds of parts and components, then the preliminary product design step is useful. Preliminary product design is all about the appearance and function of the conceived product, and less about the product’s manufacturability. Once preliminary product designs are made, they become the frameworks for the final product design.

Final Product Design:

Final product design is all about product manufacturability. In simpler words, it is about creating product designs in such a way that the said products are easy to fabricate or manufacture. The final product design specifies everything required to dictate production or mass manufacturing. It considers everything on a part level. The result of final product design is detailed drawings, 3D image and rendering files, a complete bill of materials, and details to source and assemble.

Step 3: Product Design Analyses / Feasibility Analyses

After realizing the final product design, detailed analyses are carried out on the design prior to product prototyping and prototype testing. These analyses verify the feasibility of the product, as well as its performance, like strength, weight, dimension, etc., prior to developing a physical prototype. This important step lowers the cost and performance risks related to prototype development and prototype testing. This is the third step of Steps Involved in Product Development.

Step 4: Product Prototype Development

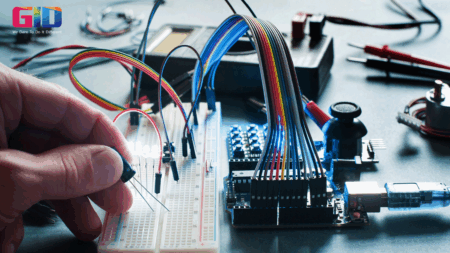

Once a definitive product design is ready, alpha and beta product prototypes are made. This is the step where the actual, physical form of a conceived product takes shape and comes into being. Product prototypes are made using suitable plastic product manufacturing techniques. If it is a product with electronics, then breadboards or generic electronic kits, like Arduino kits, are used to make prototypes. 3D printing and rapid prototyping techniques can also be utilized for product prototype development.

Step 5: Prototype Testing

Before moving the product into production, exhaustive testing of the definitive prototype is carried out to make sure that it functions and performs as expected. The prototype is used in all the possible ways it is intended to be used. The general public and potential customers are also allowed to use the prototype; this way, valuable feedbacks from them are taken and implemented before the product is sent for mass manufacturing. This is 5th Setp of Steps Involved in Product Development.

Step 6: Hazard Analysis

The hazard analysis is performed throughout the product development process. It is, however, finalized before the product is sent for production. The purpose of hazard analysis is to identify any possible safety issues that may surface by the product, in the future. If possible, the safety issues will be addressed by the change in the product design. If not, it will be addressed by the accompanying product manual and safety warning labels.

Step 7: Mass Manufacture & Release

The final step of steps involved in product development is placing the product into production. If the capital is not a constraint, then an own production facility can be set up. If it is a constraint, then outsourcing the production is a sensible and economical way. This is final step of Steps Involved in Product Development.

Once the product starts to roll out in larger quantities, it can be taken to the market, into the hands of potential customers.

Product development is indeed a time-consuming, mentally-challenging, and exhausting task. For individual inventors, it is next to impossible to realize their dream products on their own. Fortunately, there are product development companies, like GID Development Corporation, that can help inventors with product development.

Navigating the steps involved in product development can be challenging. For assistance, GID Development Corporation, a leading product development company in the US, offers expert services to help turn your innovative ideas into reality.

With their vast experience, professionals at GID Development Corporation can help develop large, complex products, products with embedded software, sports products, products with electronics, electromechanical products, and other unique products. No product development project is too big or too small for them; these professionals at GID Development Corporation will “GET IT DONE!”

Get the Best Product Design and Development Services

Are you an Inventor, a Startup, or an Established Company that wants to turn your product idea into a profitable market-ready product? Contact GID Company today! As a leading Industrial Design and Development Company, we serve different industries and offer the best services for Mechanical Design, Medical Device Design, and Life Safety Product Development.

Request a Call Back or Request a Quote today. With years of experience, we offer the best product development services in California, Florida, and nearby areas. Experience the best concept development, product design, new product development, and product prototyping services. These were the Steps Involved in Product Development.

You can also follow our blog to stay updated with the latest trends related to product design and development. Feel free to Contact Us or call us at +1714-323-1052.