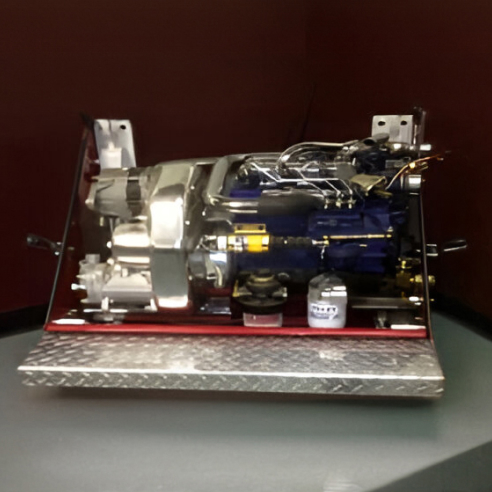

Product Features:

The Auxiliary Power System is highly fuel efficient and consumes only 0.2gal/hr. compared to the main engine at idle, which consume 0.8-1.5gal/hr. Also, the APU provides significant emission reductions compared to the idling of the main engines, which according to DOE estimates are responsible for 7.6 million tons/yr. Of CO2, 140,000 tons/yr. Of NOX and 2,400 tons/yr. Of CO. Particulate matter is completely eliminated via special filtration of the exhaust from the APU’s small diesel power plant.

To develop your idea from concept to reality, get in touch with our experts to commence your product development process with our trusted product development company in California.

DOWNLOAD CASE STUDY

Not Sure Where To Start?

Call JIM

Frequently Asked Questions - FAQs

-

What was the primary objective of the Willis Auxiliary Power Systems project?

The goal was to design a compact, reliable auxiliary power system to provide backup power solutions for industrial, commercial, and residential applications. It needed to integrate seamlessly with existing setups and operate efficiently in emergency scenarios.

-

What challenges did GID Company face during the development of this power system?

The main challenge was designing a system that could handle diverse power requirements across different industries while remaining compact and portable. Additionally, optimizing for fuel efficiency and reducing noise levels were critical hurdles.

-

How did GID Company address portability and ease of use?

We developed a modular system with a lightweight yet durable casing for easy transport. The interface was designed to be user-friendly, incorporating an intuitive control panel for quick setup and monitoring.

-

What materials were selected for the power system, and why?

High-strength, corrosion-resistant materials such as reinforced steel and aluminum were used for durability and longevity. These materials ensured the system could withstand harsh environments and heavy-duty use.

-

How did GID Company optimize the system for fuel efficiency?

We integrated advanced fuel management technology, allowing the system to adjust power output based on real-time demand. This not only conserved fuel but also reduced emissions, making it more environmentally friendly.

-

Was the system tested in real-world conditions?

Yes, the Willis Auxiliary Power System was tested under various environmental conditions and load scenarios. These tests ensured its reliability and performance in both routine and emergency applications.

-

What makes the Willis Auxiliary Power System stand out from other backup power solutions?

This system excels in portability, durability, and efficiency. Its modular design and advanced fuel management make it adaptable to a wide range of applications, while its quiet operation and user-friendly controls set it apart from competitors.